3D Printing: A Coming of Age Story

What’s the Latest Development?

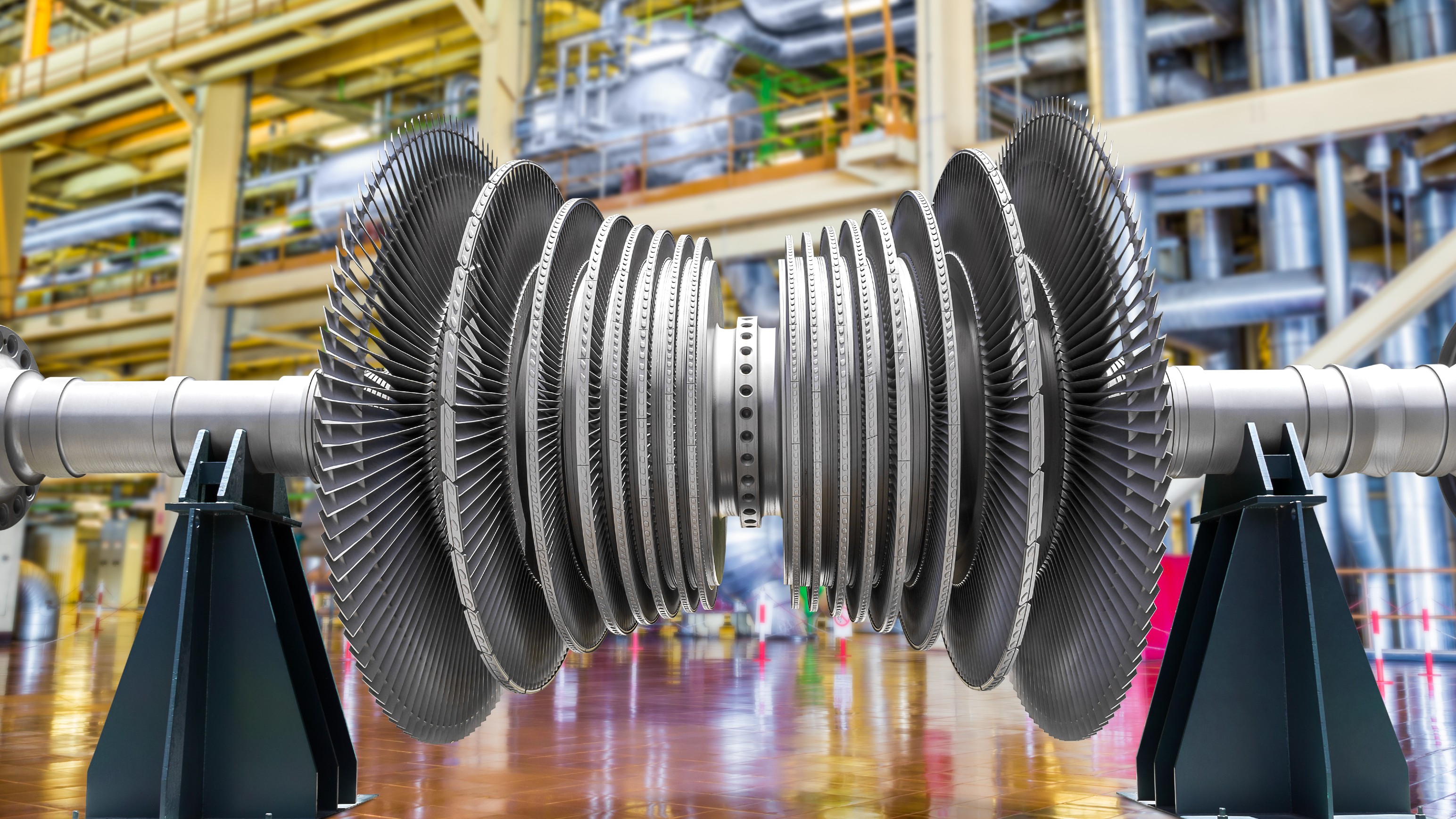

3D printing is taking on an increasingly large role in the manufacturing processes of large American companies like GE. The airplane manufacturer uses a laser to trace out the shape of plane components, such as a fuel injector, “on a bed of cobalt-chrome powder, fusing the powder into solid form to build up the parts one ultrathin layer at a time.” Aerospace companies have been at the forefront of the technology because airplanes often need parts with complex geometries that fit in jammed compartments.

What’s the Big Idea?

The future of 3D printing technology is often imagined as a series of individual inventors, all working on their unique projects, afforded an inexpensive prototyping process by 3D printers. But there is a larger, more traditional role for 3D printing: There are already 20,000 parts flying in military and commercial aircraft made by Boeing, and despite how slow the 3D printing process is, major manufacturers increasingly want to use the technology to produce specialty parts not well suited to traditional manufacturing.

Photo credit: shutterstock.com