If You can Make it Here, You can Make it Anywhere: NSG Talks with Jason Dunn

While the vast majority of mainstream press attention (and capital) focuses on the 1st through 3rdVerticals, some of the real paradigm shifting technologies and approaches may be in the 4th and 5th Verticals. There is much emphasis on reduced launch costs due to space hardware on Earth creating fundamental limits in terms of size, cost, and capability of what we can develop for space. While the limits of today may improve tomorrow (especially due to reduced launch costs), innovative thinking beyond the 2nd Vertical may produce even greater technological progress 62 miles and above.

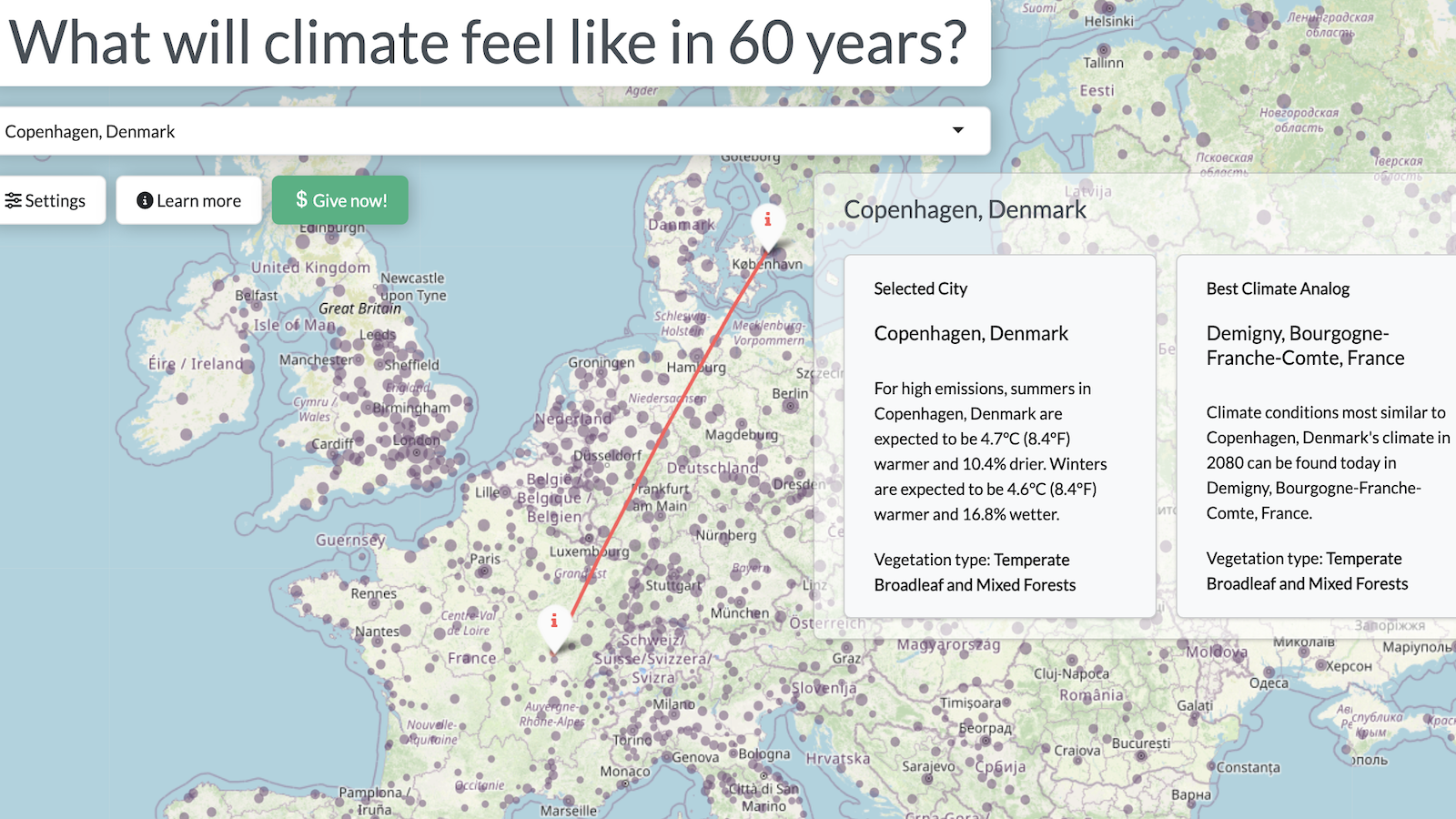

Jason Dunn (left) with NSG’s Paul Chestnut (Photo credit: Franklin Moore)

Made in Space is potentially one such NSG 100 SmallCap capable of solving this problem. MIS founders are taking a radically different approach and re-framing the very questions raised. (For instance, what if virtually all we need in space could be created there rather than built on Earth and shipped to space?) MIS isn’t looking to change the manufacturing game on Earth; they are looking to revolutionize industrialization in space. (Please see “Space Scalable” in the March 2012 issue of Thruster.)

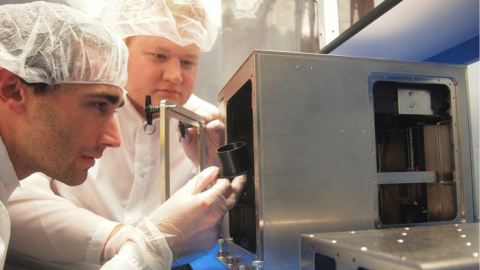

MIS formed in 2010 to enable space manufacturing. The first goal was to put a 3D printer on the International Space Station (ISS) with a simple three phase procedure: 1 – Learn how to make a 3D printer work in microgravity; 2 – Design a printer; 3 – Launch it. They have already successfully finished Step 1 with a NASA Flight Opportunities Program contract in 2011, in which they collected over two hours of manufacturing time. (Please see “SmallCap Review” in the April 2013 issue of Thruster.) In 2012, they were able to check Step 2 off the list with another NASA contract to design their 3D printer. And earlier this year, they announced progress on Step 3, with a NASA contract to put the first 3D printer in space on the ISS. (Please see “NewSpace Timeline” in this issue of Thruster.)

MIS isn’t planning on stopping at one 3D printer on the station. The company is looking to build a permanent manufacturing facility on the ISS. After the first printer goes up next year and is tested, a permanent 3D printer, designed to be upgradable, will be launched in 2015. The system will be there for the life of the space station. MIS hopes to give astronauts the ability to build whatever they need, when they need it.

We recently had the opportunity to talk with CTO Jason Dunn about how his company MIS is looking to change the face of the NewSpace industry.

1. Please tell us a little about yourself and your background.

I’ve got this insane passion for helping open the frontier of space. It’s something I’ve really dedicated my life towards; this really big goal of helping make our species multi-planetary. I grew up on the Gulf of Mexico exploring the mangroves and the estuaries on my boat. I’ve always had that knack for exploring, which led to the idea of exploring space. I went to school at the University of Central Florida because I wanted to be close to Kennedy Space Center. I worked there as an intern, and saw the Shuttle program retire. I was watching literally thousands of people be laid off at the Cape. I was watching the entire space industry change.

I kind of always thought that meant that I would work for NASA or some big contractor like Lockheed, but it was in 2006 that I first heard about this NewSpace industry and how you could be an entrepreneur. In 2008, I was in grad school at UCF and the Google Lunar XPrize (GLXP) had just been announced. A few friends and I realized it was feasible. That’s when my first space company (EarthRise Space Incorporated) was born in October of 2008… we were registered as a competitor in the GLXP and became the first and only team to be led by students. In 2009, I graduated with my Masters Degree and ended up finding my way out to California in the summer of 2010 to attend a program called Singularity University. It was there I found my co-founder, Aaron Kemmer, who came with the same mission: to create a space company to solve a really big problem. He came with a business background. Luckily, I was coming with an engineering background and the two of us, and a few others, created the idea of Made in Space.

2. Why did you form Made in Space and what problems do you seek to solve with this NewSpace company?

The interesting thing, for me at least, is that [space] encompasses every one of humanity’s grand challenges. I know that is a big statement to make, but if you think about it, when we have to learn how to live in space and be one hundred percent self-sufficient, we can’t rely on Earth. We need to be able to collect our own energy, produce our own food, recycle our own waste. We need to do all of these things through developing new technology that will allow us to do it. All of those technologies are the same technologies that we need to solve problems here on Earth like the energy problems, water, and food. By developing space, we can solve problems on Earth and make life better here… Everything that we ever put into space had to come from the surface of this planet and that really produces most of the problems and constraints that we have. That’s why we over-engineer everything to survive launch. That’s why we have to spend decades designing missions because we don’t have any chance for failure. It takes way too much time and too much energy and human resources just to put stuff into space today. [Made in Space] looked at the problem and said how can we turn this on its head? What if we didn’t have to launch anymore? What if we could build the things we need in space, rather than on the ground? That’s the idea of space manufacturing.

3. When tracking NewSpace companies, NSG Analysts use the NSG 4 Screens to assess over 300 privately-held companies in the NewSpace industry. The first and most important Screen is Management. Please describe Made in Space’s management today.

Made in Space is a really big idea. It isn’t the brainchild of one person, it’s the brainchild of this team. I’m the CTO and one of the co-founders. Aaron Kemmer is the CEO and other co-founder. One of the initial founders is Mike Chen, who is also basically our Chief Strategic Officer. Both of them are Internet entrepreneurs who weren’t in the space industry, but they bring very fresh outlooks on building a space company. It’s really interesting for me to come with a space background and build a company with two people who have really good business sense and aren’t really jaded by the way the space industry has been run in the past. We’re all pretty young and we have a strong team of advisors who have decades of experience in both the 3D printing industry and advanced manufacturing industry.

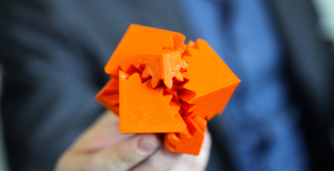

3D printing might herald a revolution in production

Our lead advisor is Dan Barry, a three-time Shuttle astronaut. He’s been here since the beginning and is listed as a founding partner of Made in Space. On this one contract we’re working right now, Planetary Resources acts as an independent review board for us. We have access to Chris Lewicki, Chris Voorhees, and the Planetary team. We have done design reviews with them and we are basically pulling in all of the knowledge base that they have. Most of their team has designed things like the Curiosity rover and other big space missions. We are able to leverage that experience in the design of the machine that we are building.

4. Another tool that NSG Analysts use is the 8 Verticals of NewSpace, which looks at the eight different markets in the industry. This issue covers those markets in the 4th through 8th Verticals of NewSpace. The 4th Vertical is Microgravity Research. How is your company generating revenue in the Microgravity Research Vertical?

We have been pretty lucky. We actually haven’t had to raise any money. In the beginning, we started with the founders’ own money. Pretty quickly, we started to get our NASA contracts which have funded the entire company so far. We have a Flight Opportunities contract but that is purely just flights. The amount of flights we’ve had today from Flight Opportunities equates to over a million dollars of money spent if you look at the cost to use the plane for the amount of parabolas we’ve flown. (Please see “Space Scalable” in the March 2012 issue of Thruster.) It’s really our [Small Business Innovation Research (SBIR)] contracts that have provided the revenue for the company. We got a Phase 1 SBIR in 2012 to design the printer. Today, we’re actually in Phase 2 and 3 at the same time. We’re developing under the Phase 3 the printer that flies to the space station next year with NASA Marshall and the Phase 2 is our permanent facility. We’ve done something that most SBIRs don’t get to do and that’s jump straight into a Phase 3 the same time as we do a Phase 2.

5. The 3rd of the NSG 4 Screens is Capitalization. Please explain to our readers how your company has been capitalized to date. Have you considered raising outside capital? And what advice do you have for other NewSpace entrepreneurs seeking to raise private capital?

Of course, we’ve thought about raising outside capital. The question is why do you need to? We’re able to do quite a bit with the money and contracts that we have. We have a pretty big R&D focus. The reason why we’re so adamant against raising capital until we know we need it is to retain the ownership in this company. We have a very important vision and to be able to maintain that as much as possible is important to us. It’s important for other people that are trying to become space entrepreneurs to understand why you raise capital and understand that it is someone else’s money that you are about to spend.

6. The last of the NSG 4 Screens is Technology. Please explain to our readers some of the innovations that your company has built to date. What technologies are you planning on developing in the near and long term?

What we’ve focused on since we’ve formed is building manufacturing technologies for space, primarily 3D printing technologies. Back in 2011, when we flew the zero gravity flights, we were flying commercial 3D printers and our hypothesis was that they would work fine. We learned that the commercial printers actually didn’t work fine and that each one needed some kind of modification to work in microgravity. In the end, we built a printer that worked through every gravity regime the plane sees from 2Gs all the way to 0Gs. By developing the printer this way, we actually developed a gravity-independent 3D printer. That’s something that really didn’t exist before. After that, we started designing the printer for the space station. It really needed to be rugged, reliable, and easy to operate for the crew. It can survive launch into space and EMI interference. The product that we have developed is a very advanced extrusion-based 3D printing technology, but the company wasn’t formed to put a 3D printer on the station. It was formed to enable space manufacturing. We’re always working on the technologies that will enable that. If you look at a timeline of the things we would start building, in the beginning, it is small things like we’re doing now, tools and spare parts on the space station. Very soon after that, we will be able to build small satellites on the space station. (Please see “Space Scalable” in the March 2013 issue of Thruster.) Later on down the road, you can start imagining the huge variety of the things that could be manufactured in space. (Please see “SmallCap Review” in the July / August 2012 issue of Thruster.)

7. There are a number of 3D printing technology companies in existence now. Several have gone public (like ExOne) and we just saw the former NSG 100 Makerbot acquired by the NSG PTCStratasys. How can Made in Space leverage the growing popularity in 3D printing to boost its own brand?

We are already doing that and we are doing a pretty good job at it. We started with really strategic partnerships. 3D Systems and Stratasys are both partners with us and those are the two leading 3D printing companies. 3D printing has helped bring attention to what we’re doing. In 2010, 3D printing wasn’t being talked about like it is today. People are still looking for the “killer app” of 3D printing. For us, space is the killer app. Once you start realizing what it could do, it makes a lot of sense. MIS has helped bring attention to the 3D printing industry and vice versa.

8. Made in Space and NASA have recently joined to launch equipment for the first 3D microgravity printing experiment to ISS. What is the timeline for the ISS experiment and are there any other tests scheduled?

It is scheduled to launch on SpaceX mid next year. We are about a year from launch and less than a year from delivering the printer to NASA to get it ready for launch. There’s quite a bit more, unfortunately it is not something that is public to talk about right now but what I can say is that we have lots of different ideas in the works. We also have a concrete mission being designed, and it focuses on increasing the capability of what these initial 3D printers can do and to provide the closed-loop of manufacturing in space.

9. With the growing number of NewSpace companies, where do you see the industry over the next 5 years? How about over the next 10 years?

I see a new era of the space industry and space exploration; the era of the individual to get involved. There are so many people on this planet that are fascinated by space. I envision those people getting involved. That’s something that here at MIS we’re really trying to help enable. In the next five years, we’ll see it going really strong. In 10 years, we’ll see satellites that are so cheap and easy to build that it’s just like launching your smartphone into space. We’re going to see people having their own space missions and take over where the government has been for so long.

Paul Chestnut is an Analyst Intern with NewSpace Global and a first-time contributor to Thruster.