Want to Save the Manufacturing Sector? It’s Time to Embrace the Principles of Next Generation Manufacturing

Like most industries, the manufacturing sector is transforming rapidly. Because of recent technological advances and globalization, U.S. manufacturing is facing intense international competition, increasing market volatility and complexity, a declining workforce, and a host of other challenges. Yet we know that in order to have a strong economy, we need a strong manufacturing base. So what’s the answer?

Today’s manufacturers must transform along with the rest of the world by adopting Next Generation Manufacturing principles. And while many manufacturers have started to adopt some next generation manufacturing principles, there are six advanced principles they need to embrace in order to move forward now. Let’s look at both categories—the current and the advanced.

Current Next Generation Manufacturing Principles in Practice

Six Advanced Next Generation Manufacturing Principles to Adopt

Fortunately, most manufacturers have already adopted the previous mentioned principles. To take the manufacturing sector to the next level, here are six more advanced next generation manufacturing principles to employ.

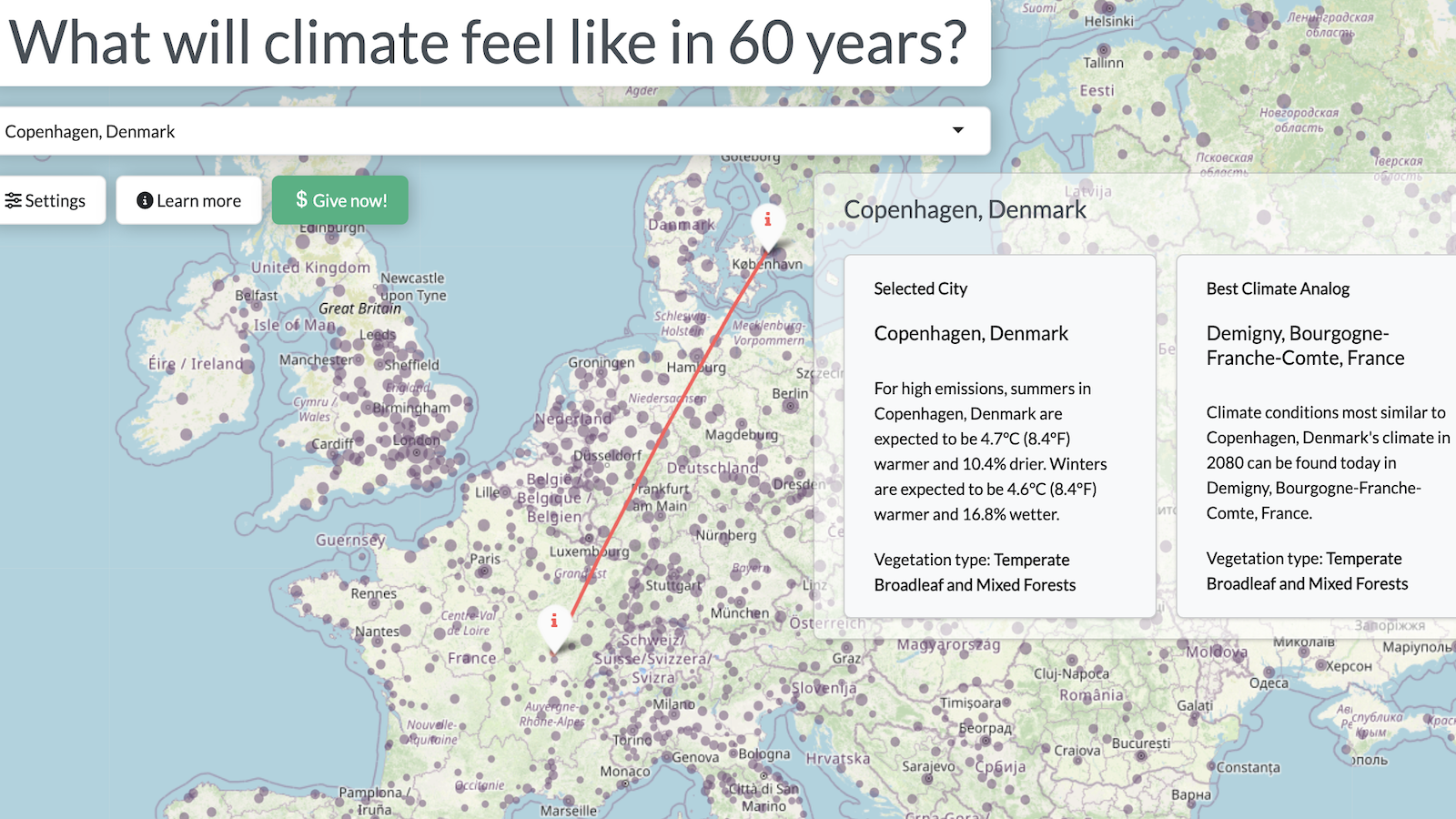

It’s vital that manufacturers anticipate customer needs based on hard trends. Therefore, look at your customers’ future and focus on what you DO know rather than what you don’t know. Ask, “What are the hard trends, the things that will happen, versus the things that might happen? What are the industries that are converging around our customers that our customers currently don’t see?” Then you can start seeing both needs and opportunities before they happen.

One of the reasons you need to be more anticipatory is that things are changing so fast. Typically manufacturers ask the customer what they want and then give it to them. But by the time you have it designed and manufactured and give it to them, their needs have changed or the economy has shifted again. The relevancy of the need is no longer as great. Second, if you ask customers what they want and give it to them, they’re going to under-ask, because they’re focused on what they know is possible, not what you know is possible. Customers, just like most companies, don’t know how to anticipate. But when you adopt this principle, you’ll be able deliver what your customers need just as they need it.

What are your core competencies? Are you still using your core competencies? In the past, manufacturers could go decades between innovations. That strategy doesn’t work anymore. The world has changed, and more important, change itself has changed. Information and new knowledge now travel around the world at the speed of light, and technological innovation proceeds at close to the speed of thought. Today you cannot just innovate now and then: to survive and thrive in a time of vertical change, you have to be innovating around your core competencies continuously. So what is your core, and are you using it?

Also consider if there’s a new core you need. Because of the rapid transformation we’re going through right now, which is driven by technology, there may be a new core you need to develop or to acquire.

We are transforming how we collaborate right now. Realize that collaboration is much different than cooperation. Cooperation is based on scarcity and it contains within it the assumption that your interests and mine are inherently in conflict; however, we will temporarily set aside those cross-purposes to find some cautious tactical common ground. In essence, cooperation is about protecting your piece of the economic pie and doing everything you can to make it bigger. In contrast, collaboration is when we co-create the future together. It’s about working with everyone else, even your competitors, to make a bigger pie for all. It’s based on abundance and requires working together under higher levels of trust and connectivity.

The move from scarcity thinking to abundance thinking, from zero-sum competition to one-hundred-sum collaboration, is not just a “nice” or “moral” idea. In the twenty-first century, it’s plain good sense. Scarcity says, “I’m going to keep all my ideas to myself and sell more than anyone else.” Abundance says, “By mentoring, coaching, and sharing all our best ideas, we’re going to create a powerful tide that raises all our ships—and we’ll all sell more as a result.”

The best way to avoid problems is to use hard trends to both predict and pre-solve them. Based on my own studies of manufacturing firms and other companies, I’ve found that 98% of the biggest problems companies faced were fully predictable before they happened. This is hindsight, and hindsight always brings lament.

Hard trends add certainty to foresight. If a problem is fully predictable, that means it’s fully avoidable. Therefore, manufacturers have to use those hard trends to look into the visible future and ask, “What are the problems that we can see based on anticipating customer needs?” Get that down to a short list that’s aligned with your core competencies. Then that’s where you focus, because you can see which problems are coming. Additionally, look at your own company in the same manner to determine the problems you’re about to face. Solve them before they happen so they don’t occur in the midst of rapid change and transformation. That’s the only way to stay ahead of the curve.

In the past, we developed information-age organizations. As a result, companies do a lot of informing and are very good at it. But most are not good at communicating, both internally and externally. Companies now have to inform and communicate. What’s the difference?

Informing is one-way. It’s static and doesn’t always cause action. Communicating is two-way. It’s dynamic and usually causes action. Social media is a good example of engagement in communication, which is why it’s spreading so rapidly and becoming a business tool. Next generation manufacturers understand that you don’t just inform; you also communicate, develop that strategy, and move it out internally as well as externally.

Just as we had continuous improvement in the past, manufactures need to continually de-commoditize their products and services. Realize that every product and service can be de-commoditized repeatedly. Unfortunately, most companies don’t do this. Instead, they come up with a new product or service and they milk it. They make their money on it and by default let the product or service become a commodity.

The minute you come up with something new, a competitor will copy it. As they do so, your de-commoditized and innovative product or service slowly becomes a commodity. The margins get thinner as time goes on. You find yourself competing more on price and eventually remove the product or service from your line.

Here’s a better approach: Instead of letting the margins get thinner and riding them down, you can wrap a service around a product or wrap a service around a service to add new value. You can think creatively about your product or service so you can repackage it, redefine it, revamp it, or somehow make it unique in the marketplace again. So do continuous de-commoditization. Not only will you raise the bar based on trends, but you’ll also find yourself with good margins and a growing business.

Manufacturing for the Future

In a competitive global economy that is becoming more tightly connected every day, U.S. manufacturers can no longer do things the way they’ve always been done. To be successful in the future, to stay competitive and relevant, and to revive and save the manufacturing sector, all manufacturers must adopt next generation manufacturing principles. That’s the only way to obtain the talents, capabilities, and resources necessary to build a highly effective enterprise that thrives in a global marketplace.