A new record nears: the world’s largest telescope prepares for completion

The ELT, at 39 meters in diameter, will dwarf everything that’s ever come before.

“There are so many people who are arguing or fighting over issues which don’t have much relevance. We must all realise it is not worth it. It’s like being in the whirlpools which are always present behind a little rock near a river. We seem to be living in these little whirlpools and forget that there is a whole river. The picture is much bigger.” –Kalpana Chawla

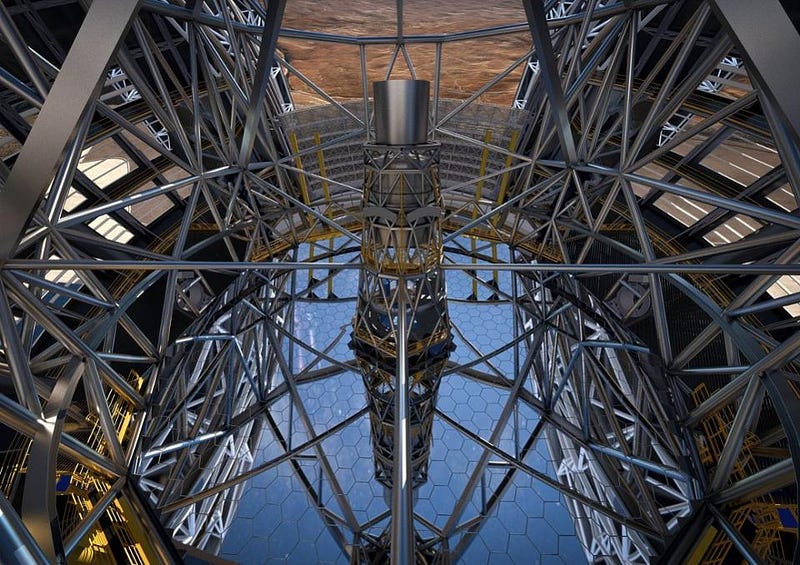

If you want to learn more about the Universe than you ever have before, there’s only so much you can do. You can improve your optics and your seeing, making your mirrors smoother and defect-free than ever before. You can improve your conditions, through adaptive optics or optimizing your observatory’s location. You can work on your camera/CCD/grism technology, to make the most of every single photon your telescope is capable of collecting. But even if you do all that, there’s one improvement that will take you beyond anything you’ve ever accomplished before: size. The larger your primary mirror, the deeper, faster, and higher-resolution you’ll be able to image anything you look at in the Universe.

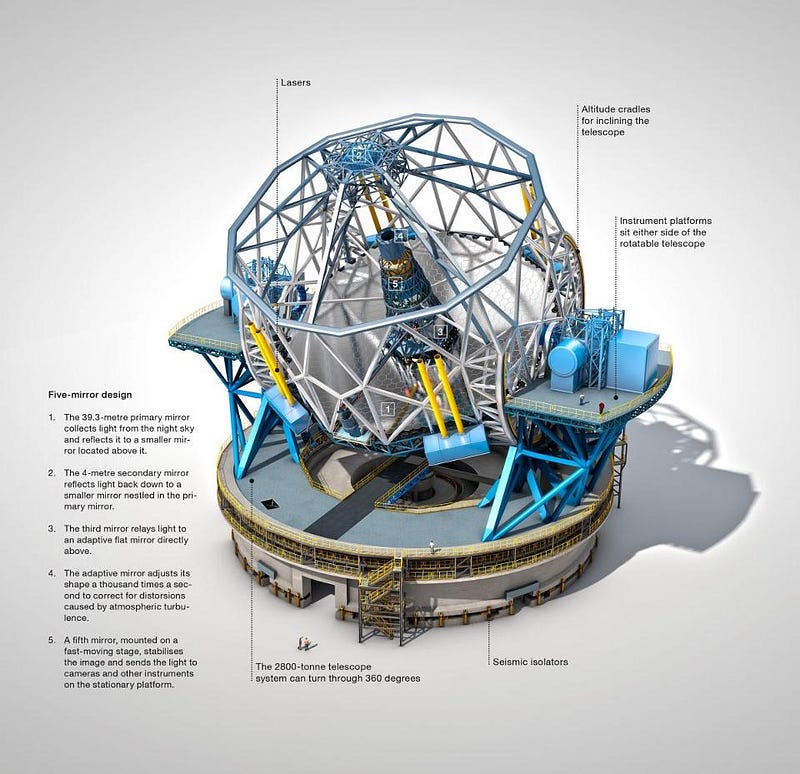

Currently, there are a number of 10-meter (33-foot) diameter optical telescopes in the world, with the Giant Magellan Telescope, at 25 meters (82 feet), poised to break that record in just a few years. But an even more ambitious project, the 39 meter (128 foot) diameter Extremely Large Telescope (ELT) by the European Southern Observatory (ESO), began construction in 2014. By time the mid-2020s come around, it will blow everything else away.

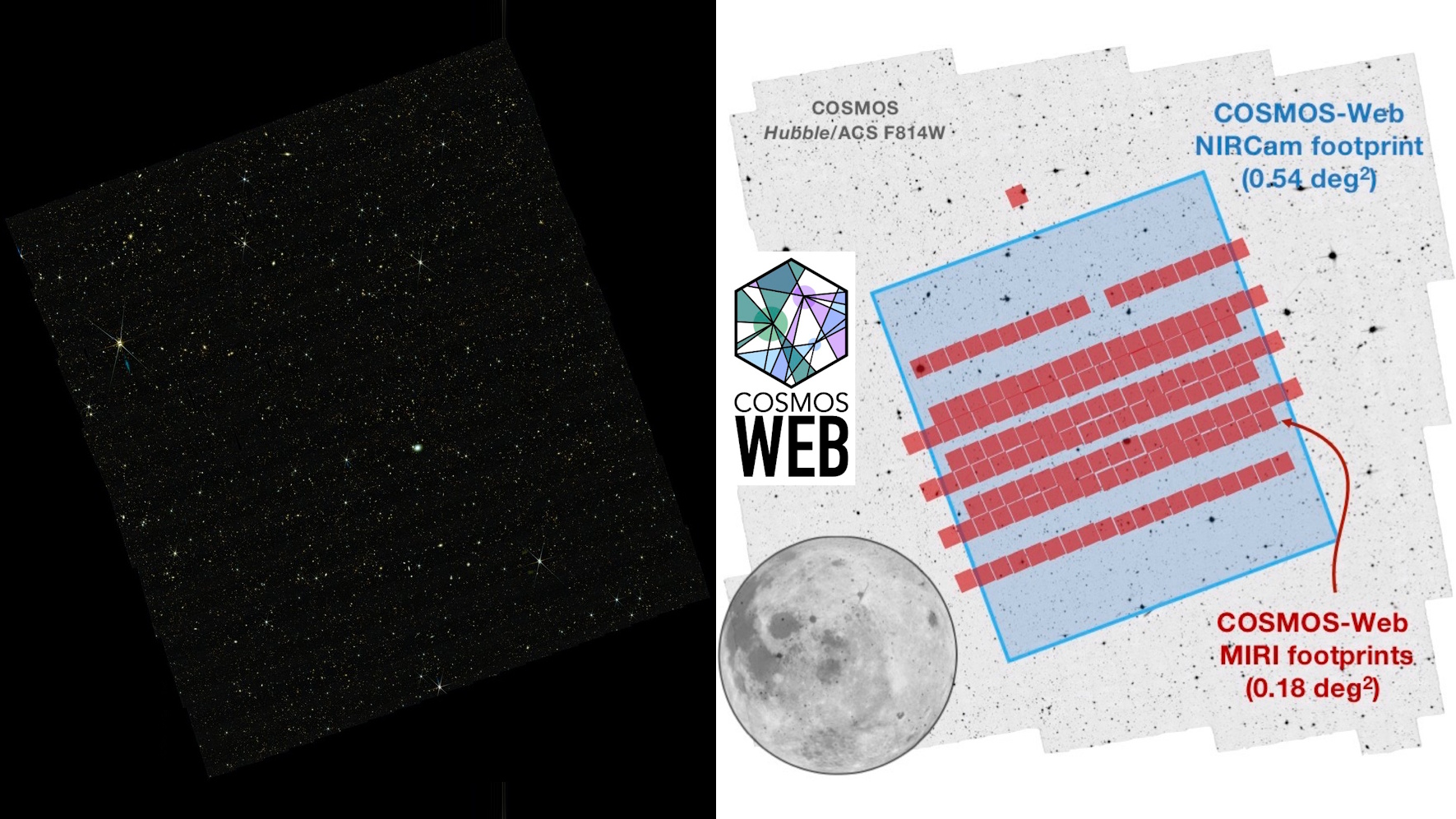

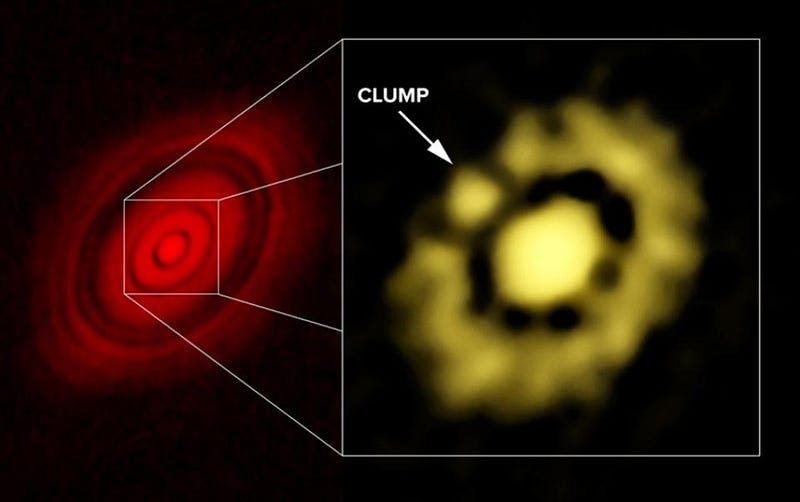

Not only will it take images that are 16 times sharper and with 256 times the light-gathering power than Hubble, but it will enable us to do science that’s unfathomable with our current instruments. We can directly detect light from extra-solar planets — planets around other stars beyond our own — and break it up spectroscopically, discerning what’s in their atmospheres. For the largest planets of all around the closest stars, we’ll even be able to take the first direct images of those worlds. It will also take unprecedented images of the most distant, earliest galaxies in the Universe; of supermassive black holes at the centers of other galaxies; will enable the detection of water and organic (carbon-based) molecules in protoplanetary disks around newly forming stars; and it will probe the nature and properties of dark matter and dark energy. With a telescope this large and high-quality, so much new science becomes possible.

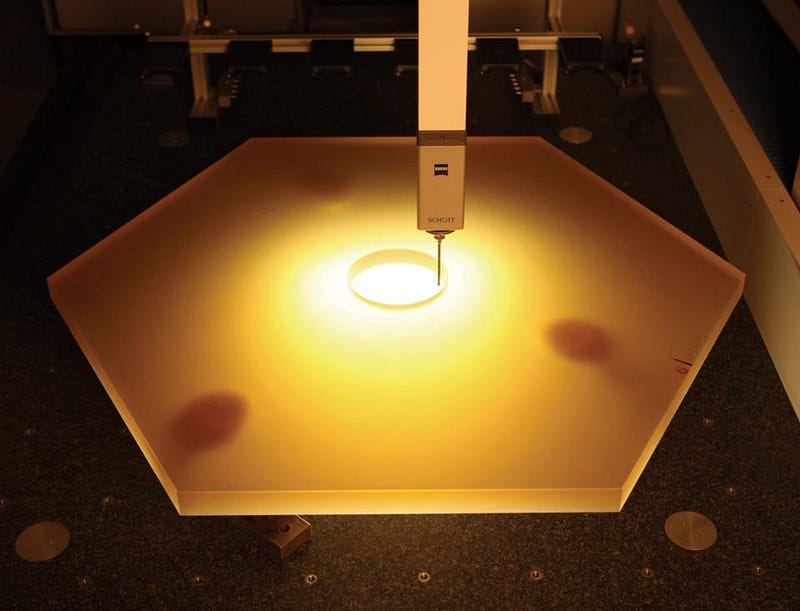

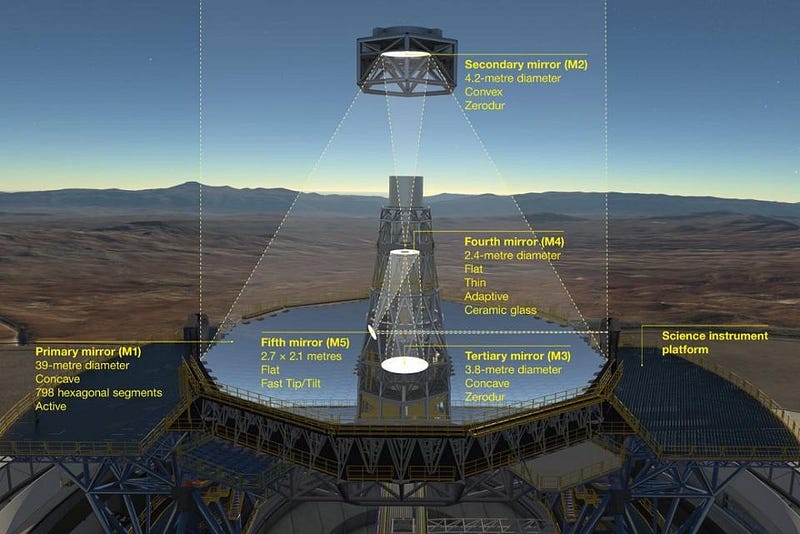

But the key to it all is the size and quality of the primary mirrors. I had the opportunity to speak with Marc Cayrel, the project manager of the optics — the eyes of the telescope — for the ELT. In order to build a telescope this large, you need to build an effective surface that’s properly shaped to focus the incoming light across an area 39 meters in diameter with a large hole in the center: the equivalent of 1000 square meters. (For comparison, Hubble’s area is 4.5 square meters.) The surface needs to be smooth down to an incredible 7.5 nanometers: just 1/100th the size of the wavelengths of light it will collect. You cannot build a single mirror that large to that level of smoothness, so the only option is to do it in segments. With material manufactured by SCHOTT, made out of their unique, low-expansion ZERODUR® material, and then polished by SAFRAN-REOSC, the ELT will boast the largest primary mirror of any optical telescope in humanity’s history.

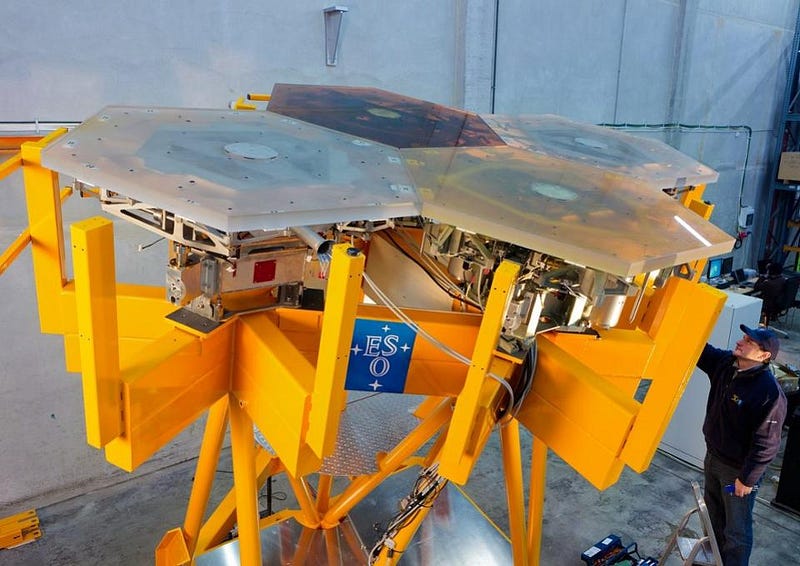

In an incredible technical achievement, the primary mirror will be built out of 798 hexagonal segments, each one 1.4 meters in size, as measured from corner-to-corner. Each segment is a mere 50 millimeters (about two inches) thick, with the mechanics underneath, forms a complete assembly that can be moved in-and-out of the telescope. Each individual segment can be polished to a smoothness of 7.5 nanometers (where that’s the root-mean-square smoothness), achieving the optical goal. The big advantage to that smoothness is image quality, since you need to be that tiny fraction of the light’s wavelength you’re collecting in order to do high contrast imaging, particularly for objects that are so far away. A special reflective coating is then physically added to the top, to make the most of every photon that comes in and strikes the primary mirror.

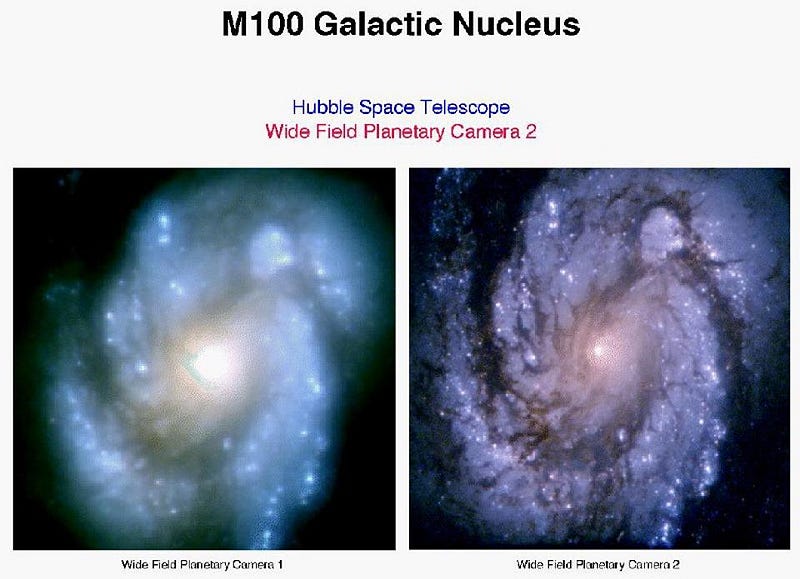

Manufacturing, polishing, and constructing these mirrors and the assemblies will take approximately seven years, as the ELT needs around 800 of them. Because they’re hexagonal (six-sided) mirrors that need to make a completed mirror of a particular geometric shape, that means that there are 133 unique shapes you need to complete the mirrors: 798 ÷ 6 = 133. If you didn’t produce them with the required gradient in your mirror shapes, you’d wind up with optical aberration, which was the original flaw with the Hubble Space Telescope! But the coatings themselves are delicate and temporary, and must be done on-site. So that means you need a dedicated production facility, where you can crank out about one mirror coating every day; even at that, it will take over two years to get all the individual mirrors telescope-ready.

Being present here on Earth, the reflective coatings on the mirror are subject to wear-and-tear. Even though the optical quality of a mirror is stable over timescales of decades, the additional layers only last for about 18 months until they need maintenance. That means stripping the mirror coating completely and applying a new coat on a continuous basis. Even if you could replace one or two every day — because the telescope is only used at night — you couldn’t possibly keep all the segments in continuous operation with just the 798 mirrors you have for the telescope. Instead, you need to manufacture an “extra” 133 mirrors, one of each unique shape, so you can replace the mirror you need to repair-and-recoat without jeopardizing the full telescope mirror, for a total of 931 mirrors.

This means, of course, that you need an extra storage facility for 133 mirrors, an on-site segment stripping and recoating facility, and to basically turn your observatory into a factory whenever you’re not viewing the sky. The plan for the ELT is to have it be in a state of continuous maintenance every day, where a mirror is removed and replaced with a newly recoated one, which means that it can be in a state of continuous operation every night.

Even with 798 perfectly configured, polished, and coated mirrors, your challenges aren’t over. You don’t just need that high accuracy surface for each mirror segment, you need that same accuracy between all of the mirrors combined, and at once. In order to get the tolerance between mirror segments down to that level of precision, you need to account for Earth’s gravity, which will deform the mirrors, and temperature differences and fluctuations. Three position actuators can align each segment assembly for height, tip, and tilt, which will align the mirrors relative to one another continuously: up to four times per second. But the other necessary alignments come from a nine-actuator warping harness that’s on the underside of each mirror segment. These actuators apply torques to compensate for the distortion of each mirror, where the shape and curvature can be optimized, producing required nanometer-level accuracy. Warping adjustments can be done several times per night, as necessary, depending on what’s being observed and what the thermal conditions are.

Next, you need to create the shape of the overall mirror that you want to achieve: what we call a “set point” for the primary mirror. By beginning your night by looking at a star and analyzing the light coming from it after it reflects off the mirror, you can determine how each of the 798 mirrors must be moved, relative to one another, to achieve that perfect focus. Once you’ve done that calibration, the mirrors are all considered phase-locked. During the night, that set point will be used for observations, achieving very good accuracy throughout.

But to maintain that set point throughout your observations, you need to make tiny, continuous adjustments to the individual mirrors. The air temperature will change; gravity will be present; there will be internal vibrations to the telescope assembly; there will even be wind effects that are substantial. It’s like seeing ripples in a lake or pond due to the wind: if you need a perfectly smooth surface, you have to clean those up. Very small adjustments will be made to each individual mirror about four-to-five times per second, which keeps you phase-locked and at that set point all throughout that night, and at that required 7.5 nanometer accuracy.

There are also going to be gaps between the individual mirror segments, along with edge effects. There are, after all, 798 mirrors with six edges each; that’s nearly 5,000 edges total! It’s very difficult to polish a mirror evenly all the way to the edge, otherwise you get “turn-down” of the surface near the edges. To overcome that, you polish a disc 1.5 meters in diameter, then carve out your 1.4 meter hexagonal segment, and only then apply your final coating. Still, the hexagonal segments, even with gaps tuned to be only 4 millimeters between each segment, will create an image artifact that can’t be avoided: diffraction spikes. Unlike Hubble, which has four spikes on each star, ELT will have six, due to the hexagonal gaps.

Even at that, there are techniques for helping out on that front. If you image something very distant or wide-field, the spikes are barely perceptible. But if you’re trying to image something faint that’s very close to something bright, that’s when the spikes are a nightmare. By minimizing the gap-space as a function of surface area — 99% of the telescope’s surface is mirror — you help minimize the magnitude of the spikes. And by using shear imaging, where you take two images that are slightly mis-positioned and then subtract them, you can remove most of the effects of those diffraction spikes.

The ELT, by the nature of its size, its power, its weight, and its complexity, could never have been a “build-it-and-you’re-done” type of telescope. It needs to be continuously adjusted throughout the night to maintain the optimal mirror shape; it needs to be re-calibrated night-to-night to achieve that perfect set point; it needs to have its mirrors recoated every 18 months to keep that ideal smoothness and reflectivity. But if you do all of that, and you use the optimal techniques and instruments — from pointing-and-tracking to adaptive optics to imaging methodology — the ELT has the capability to outclass every other optical telescope ever built, on Earth or in space. It’s going to be an incredible technical achievement when complete, an achievement that requires continuous work to maintain. But the science we’ll get from it will be unlike anything else our world has ever seen.

Ethan Siegel is the author of Beyond the Galaxy and Treknology. You can pre-order his third book, currently in development: the Encyclopaedia Cosmologica.