3-D Printer Builds Functioning Human Ear

What’s the Latest Development?

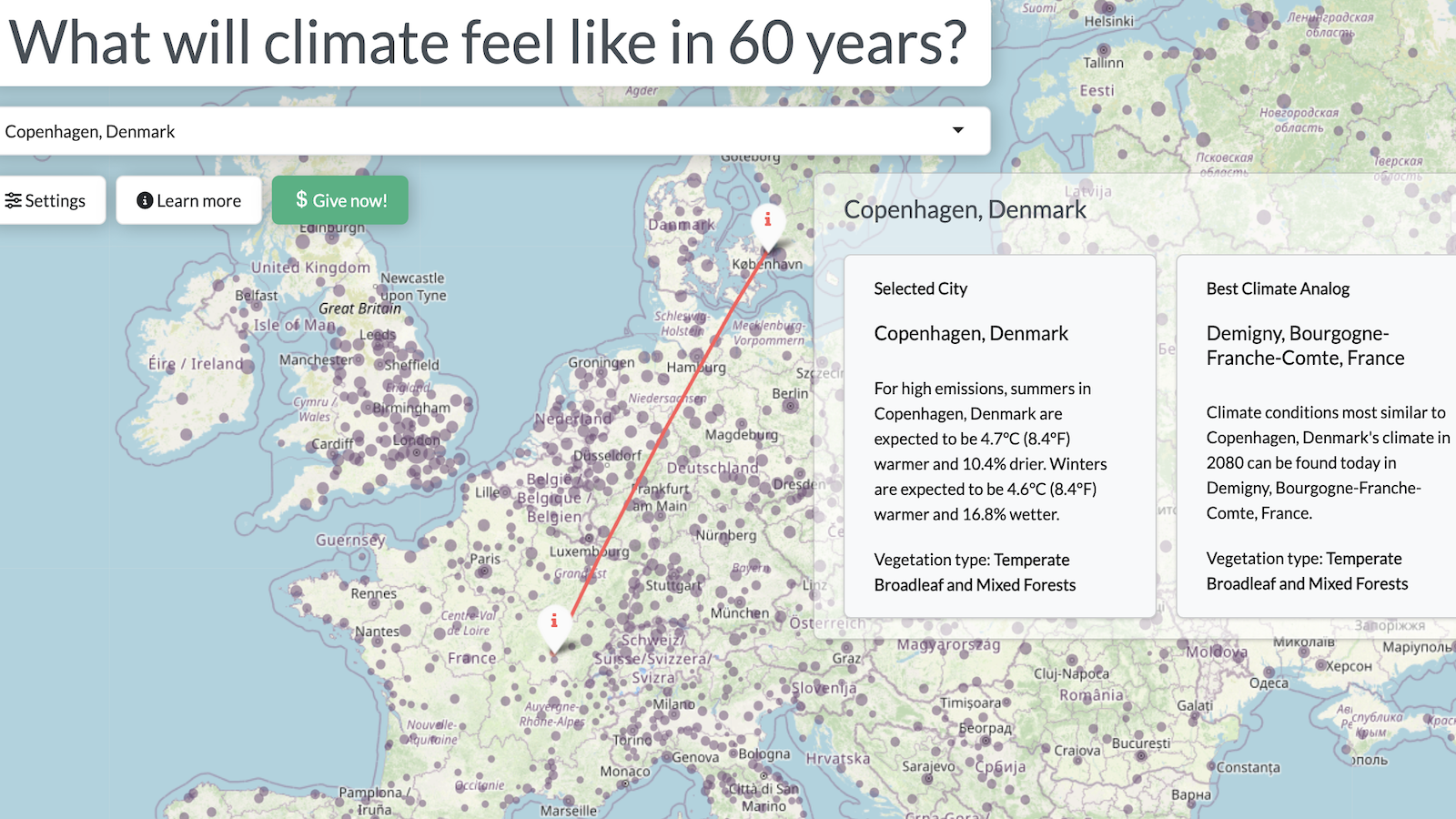

Scientists at Cornell University have used a 3-D printer to construct an artificial human ear which, when used to replaced a damaged ear, looks and functions nearly identically to the original. The project to make the ear was led by Lawrence Bonassar, associate professor of biomedical engineering. Together with his team, Bonassar started with a digitized 3-D image of a human subject’s ear, and converted the image into a digitized “solid” ear using a 3-D printer to assemble a mold. “This Cornell-developed, high-density gel is similar to the consistency of Jell-o when the mold is removed. The collagen served as a scaffold upon which cartilage could grow.”

What’s the Big Idea?

The ear is expected to benefit children born with microtia, a congenital ear deformity. In the past, the condition has required doctors to build ears from Styrofoam-like material or from patient’s harvested ribs. The process is also fast, Bonassar added: “It takes half a day to design the mold, a day or so to print it, 30 minutes to inject the gel, and we can remove the ear 15 minutes later. We trim the ear and then let it culture for several days in nourishing cell culture media before it is implanted.” A human implant of the bioengineered ear is expected to be ready in three years time.

Photo credit: Shutterstock.com