How refrigeration destroyed the massive international ice industry

In a world before refrigerators, before ice dispensed at the press of a button or the twist of an ice cube tray, ice was a luxury. An iced drink was indicative of wealth, and the ice industry was a multi-million-dollar employer.

Norway—a hub for natural ice—exported one million tons of it per year. The US market overshadowed that effort manifold. At its peak in the nineteenth century, an estimated 90,000 people and 25,000 horses were involved in the natural ice trade in the States. In fact, such was the demand for American ice in London at one point, Lake Oppegård in Norway was rechristened “Wenham Lake” (after a lake in a Massachusetts town) to compete with American ice imports in England. By 1856, American ice was shipped to all four corners of the world, including South America, the Caribbean, Southeast Asia and Australia, the Persian Gulf, and its biggest market–India.

The United States had three epicenters for ice: New York, Boston, and Chicago. Historian Peter Stott notes in The Journal of the Society for Industrial Archeology, that in 1880, “at $6,190,000, New York ice sold at a value over six times that of Boston ice.”

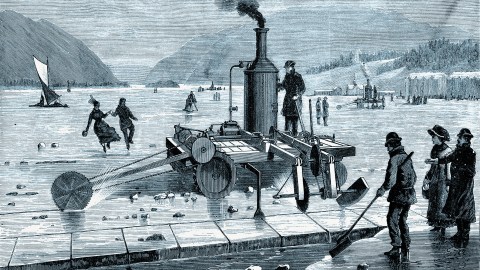

This monopoly would have been impossible without armies of ice harvesters or ice cutters—boys and men who sawed through chunks of it where it formed naturally atop ponds, lakes, and rivers. Before they could do so, note historians Linda H. Kistler, Clairmont P. Carter, and Brackston Hinchey in The Accounting Historians Journal (yes, there is such a journal!), they had to fashion the tools of their trade. In the early 1800s, Frederic Tudor—future global ice tycoon—enlisted crews to cut ice by hand. As demand grew, Tudor’s ice cutters turned to horse-drawn ice-cutters, invented by Nathaniel Wyeth. Plow-like, these horse-drawn cutters scored the ice in a uniform grid, tripling the harvest.

Canadian ice cutters, by contrast, used a different technique. They cleared the ice clean of fallen snow before cutting it by hand with a six-foot or round saw attached to a sled. So too in Greenland. A letter to the royal society for arts, manufactures and commercefrom Englishman W. J. S. Hood, a senior lieutenant aboard the H. M. S. Hyperion, documents the use of hand saws: a suspended saw “with a weight [and rope is] attached […] will require ten or twelve men.” Hood says the process would require additional men too, “making an aggregate of twenty-five or thirty.”

Which is to say: ice cutting was strenuous seasonal work. More notably, it was dangerous: the threat of men and horses drowning or being crushed by a four hundred pound block loomed ominously. A 1933 article published in Monthly Labor Review details the drowning of an ice cutter in the Des Moines River while harvesting for the Ottumwa Sand Co. two years earlier. The company, which only had an eleven-day harvest window, was ordered to pay the cutter’s widow fifteen dollars per week for three hundred weeks. While he was employed, the man had earned four and a half dollars per day for his work.

Another article titled “The Wisconsin Ice Trade” makes note that “unless stopped by intense cold or thaw,” harvesting was “often incessant day and night.” It was, after all, a race against time, otherwise known as the spring thaw.

Additionally, depending on the location of the harvest and its size, once cut, slabs of ice were pulled in using poles or picks and transported by sled to “ice houses” for storage. From here, they would be shipped globally and domestically. In the United States, the single biggest consumers of ice were beer makers. According to The Ice Trade Journal, breweries used an estimated million tons a year to make and distribute their product, and another two million tons to cool and serve it. Beyond chilling beer, ice was essential to maintaining the freshness of meat and produce.

Indeed the ice industry radically changed dietary habits, writes Stott. Thanks to it, salmon and lobster from Boston made its way to Calcutta–where, by 1833, “the first ice cream ever eaten in India was made using Massachusetts ice,” note Kistler, Carter, and Hinchey. Eventually, writes Stott, this is what would lead to the downfall of the ice harvesting industry, taking with it the need for ice harvesters: “[The] demand for ice stimulated the development of reliable means of artificial refrigeration. At the same time, the immediate success of an ice trade based on abundant ice ponds and efficient transportation, postponed the rapid development of artificial ice-making.”

Although ice harvests lingered until the 1950s—with the invention and widespread access and adoption of the ice box (and, later, the refrigerator)—by the late 1800s, harvested ice ceased to be lucrative on a global scale. Even domestically, with weather-induced fluctuations in supply, dubbed “ice famines,” “natural ice seemed to be losing its vogue,” Lee Lawrence concludes in his examination of the Wisconsin ice trade. By 1914, 26 million tons of artificial ice was produced in the United States compared to 24 million tons of naturally harvested ice.

Similarly, in India, as in the rest of Britain’s colonies, where ice cooled cocktails, entrepreneurs took steps to move toward more cost effective means of getting and selling it. In 1878 the Bengal Ice Company was formed to make ice domestically, and obviated the need for imports. This lowered its price, making it available to larger swaths of the population so that an iced drink was no longer a refreshment afforded by the wealthy. The ultimate move to refrigeration and individual ice-production means we can now eat out-of-season produce grown and harvested tens of thousands of miles away.

But convenience comes at a cost. In this case, that means the coolants needed to keep berries fresh as they travel across the world contribute to global warming. They account for ten percent of all CO2 emissions—that’s two times the amount produced by aviation and shipping combined. And the phenomenon of global warming moves us ever farther away from even the possibiity of naturally occurring ice, ultimately dooming us in a loop wherein the only way to make a frozen margarita or cool a room to provide a modicum of relief from soaring temperatures is to generate more heat.

This article appeared on JSTOR Daily, where news meets its scholarly match.