Humanoid robots are waking up — and they look eerily real

- Engineered Arts, a robotics firm located in the UK, released a video showing a humanoid robot that looks exceptionally lifelike.

- The robot is intended to act as an avatar in the real world.

- In the future, humans and robots will work together.

This article was originally published on our sister site, Freethink.

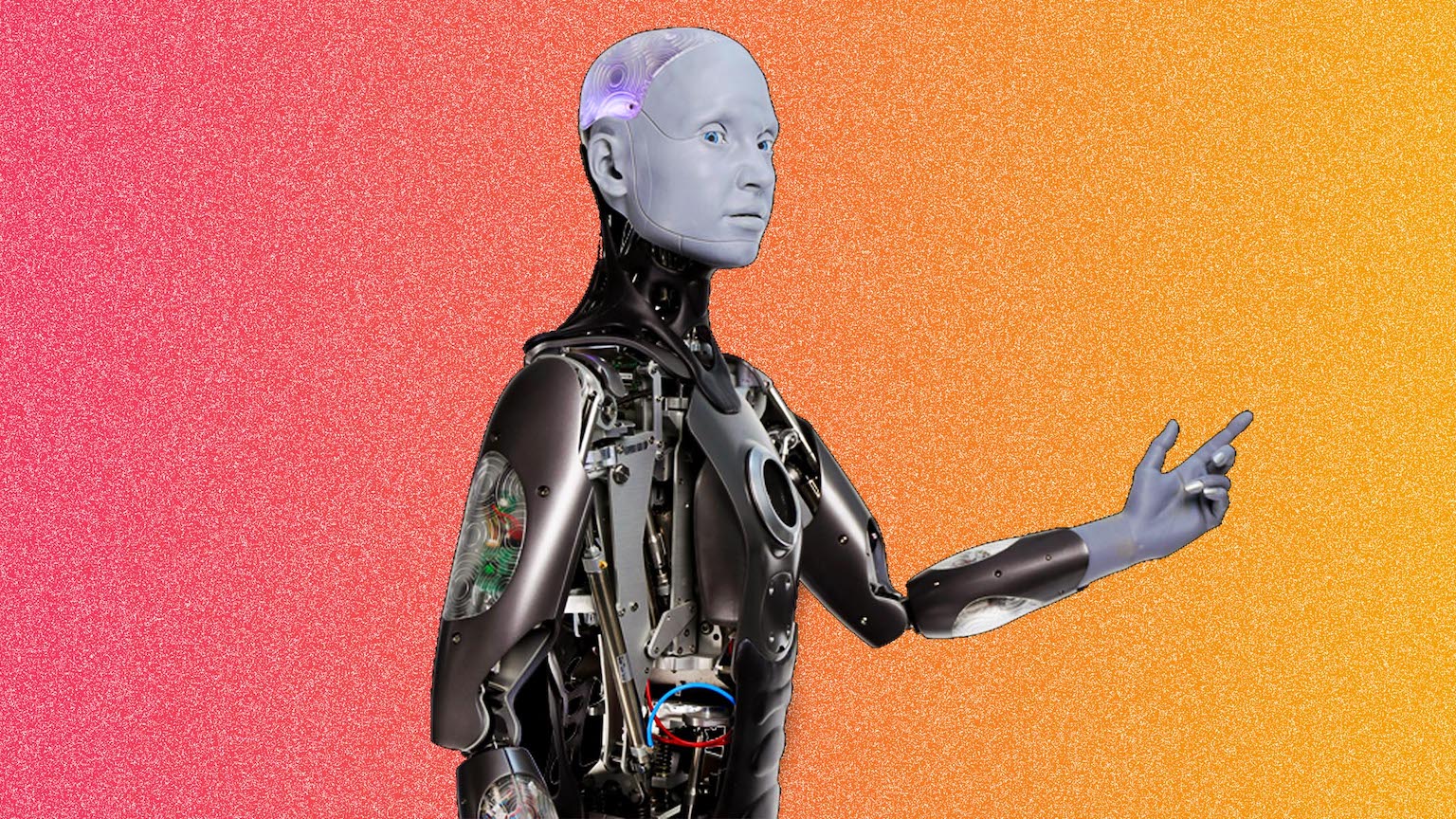

Engineered Arts, a robotics firm located in the United Kingdom, released a video showing a humanoid robot that looks exceptionally lifelike — and suddenly the science fiction movie I, Robot is trending.

The company named their robot Ameca, but Ameca’s hyper-realistic expressions and motions look eerily like Sonny, the fictional android (played by actor Alan Tudyk) who co-starred with Will Smith in the film. It may be a coincidence, or it’s one more example of science fiction inspiring real life tech.

In the Engineered Arts video, the grey-faced humanoid robot wakes up, makes a surprised expression, and then examines its own hands as if it also can’t believe how real it looks. The company calls Ameca “the world’s most sophisticated human-shaped robot” — which may be self-promoting, but perhaps not underserved, based on that video.

Regardless of how human it looks, how does it compare in terms of intelligence, and what does that mean for our future with robots?

The real-world avatar: Already next-gen robots are doing amazing things. They can chisel marble, test-drive cars, clean houses, administer vaccines, and even put in contact lenses. (Yes, we often write about cool robots.)

This isn’t the first time robotics companies have attempted to bring humanoid robots to the public, either. Hanson Robotics began mass-producing Sophia the Robot earlier this year, a social robot said to help people cope with isolation.

But if the pandemic showed us anything, it is how integrated our digital lives are with our real-world lives. With Ameca, Engineered Arts hopes to take that a step further.

According to Engineered Arts’ website, the humanoid robot will serve as a “platform for development into future robotics technologies.” Ameca can also be controlled via Engineered Arts’ cloud software, Tritium. Its purpose is to help us research human-robot interaction, and its surprisingly genuine facial cues make that much simpler.

But ultimately, the robot is intended to act as an avatar in the real world.

Imagine a typical work-from-home day. Instead of chatting with colleagues on the #water-cooler Slack channel or having a client meeting via Zoom, you could meet in person… with an Ameca-like robotic stand-in.

Ameca’s parts are modular and work independently from each other. So, the humanoid robot, now available for purchase or rent, can be deployed as a disembodied head or arm, if needed, reports the New York Post.

“The modular architecture allows for future upgrades, both physically and software, to enhance Ameca’s abilities, all without having to fork out for an entire new robot,” Engineered Arts stated.

Robotics in the real world: Seeing a robot with a humanlike face sent many people’s thoughts directly into sci-fi drama (the androids in I, Robot weren’t exactly friendly).

But robots aren’t designed to take over the world. Most robots take over risky jobs, like fighting fires, and tedious, repetitive tasks requiring high precision, like sorting recycling. In some instances, like performing surgery, precision can mean life or death, making robots the more reliable option.

Some industries are also currently experiencing a labor shortage, and the robot workforce is stepping up. Labor shortages are contributing to increased automation. McDonald’s is testing an AI as a drive-thru attendant. And Flippy ROAR, the robot cook, is flipping burgers and making fries.

But robots won’t just replace people: humans and robots working together can help businesses become more efficient, and research with Ameca could improve that collaboration.

H. James Wilson, managing director of information technology and business research at Accenture, said BMW’s use of collaborative robots is helping the company meet the rising demand for individualized vehicles.

“These human and machine teams, these robot and assembly worker teams, are about 85% more productive,” he said, reports Fortune.