Robot morphs shape using material inspired by origami

- A new metallic mesh can be used to build highly flexible soft robots.

- The material can be extremely contorted and then melted back into its original form repeatedly.

- The design of the soft robot is based on the Japanese art of kirigami, a variation of origami in which paper is both cut and folded

Although robots like Boston Dynamics’ Spot or the manipulator arms that assemble automobiles can perform some pretty impressive feats, they are still rather limited by their fixed shape. Certain applications might require a robot that’s a little more flexible. A paper recently published in Science Robotics describes a new type of robot that aims to meet those needs.

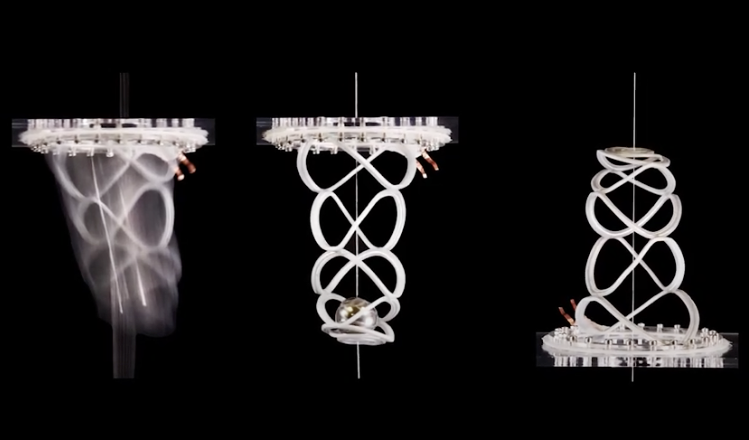

Using a “shape morphing” material, researchers designed a robot that can be transformed from a flat shape into a variety of complex forms. Although the robots built for the study serve more as a proof of concept rather than an industry-ready product, the design marks an advance in the field of soft robotics by demonstrating a material that’s soft enough to change shape yet sturdy enough to support different functions.

A mighty morphing material

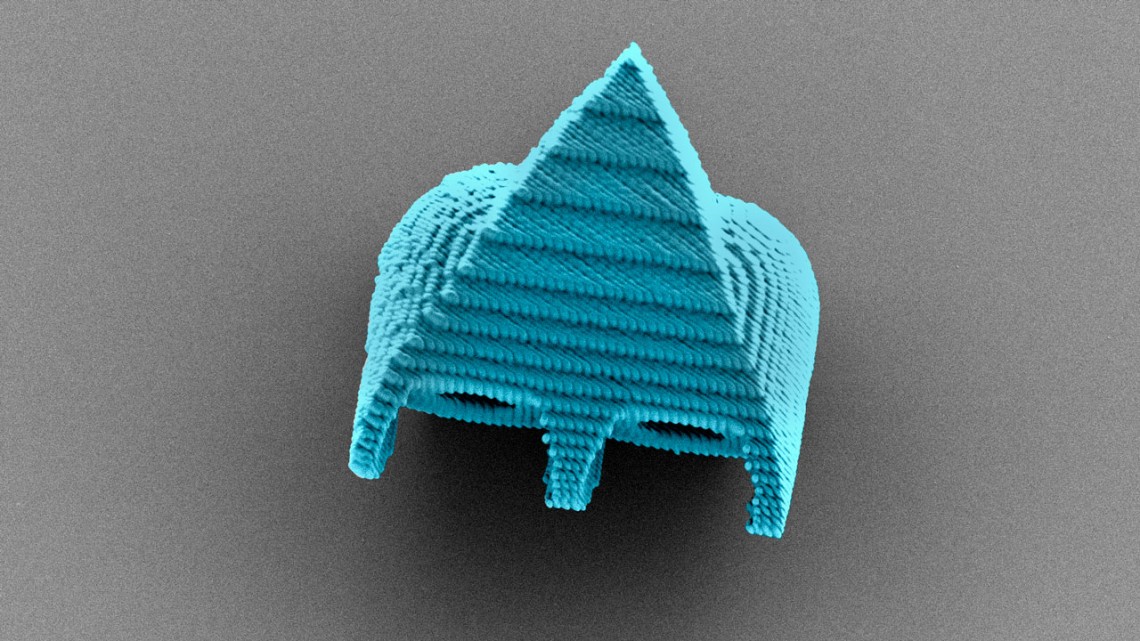

The material consists of tubes of metal embedded in sheets of rubber. These sheets are structured into patterns based on the Japanese art of kirigami, a variation of origami in which paper is both cut and folded. (In recent years, the structural benefits and malleability offered by kirigami-based designs have inspired numerous engineering research teams.)

Initially a flat mesh sheet, the material can be morphed into complex shapes as the situation requires. When a new shape is needed, the mesh is bent into a new structure. To get it back to its original form, small heaters in the mesh melt the metal — a special type of metal called a low melting point alloy — while the rubber tubing returns to its original shape. The metal then re-solidifies.

This process can occur in as little as one-tenth of a second, and it can be repeated numerous times without failure. Importantly, if something does break, it can be repaired by heating and reshaping the composite. Taken together, the material has what its creators call “reversible plasticity.” This allows for some pretty remarkable things, like the robot transforming from a ground-based vehicle into a small flying drone, and then back, without damage.

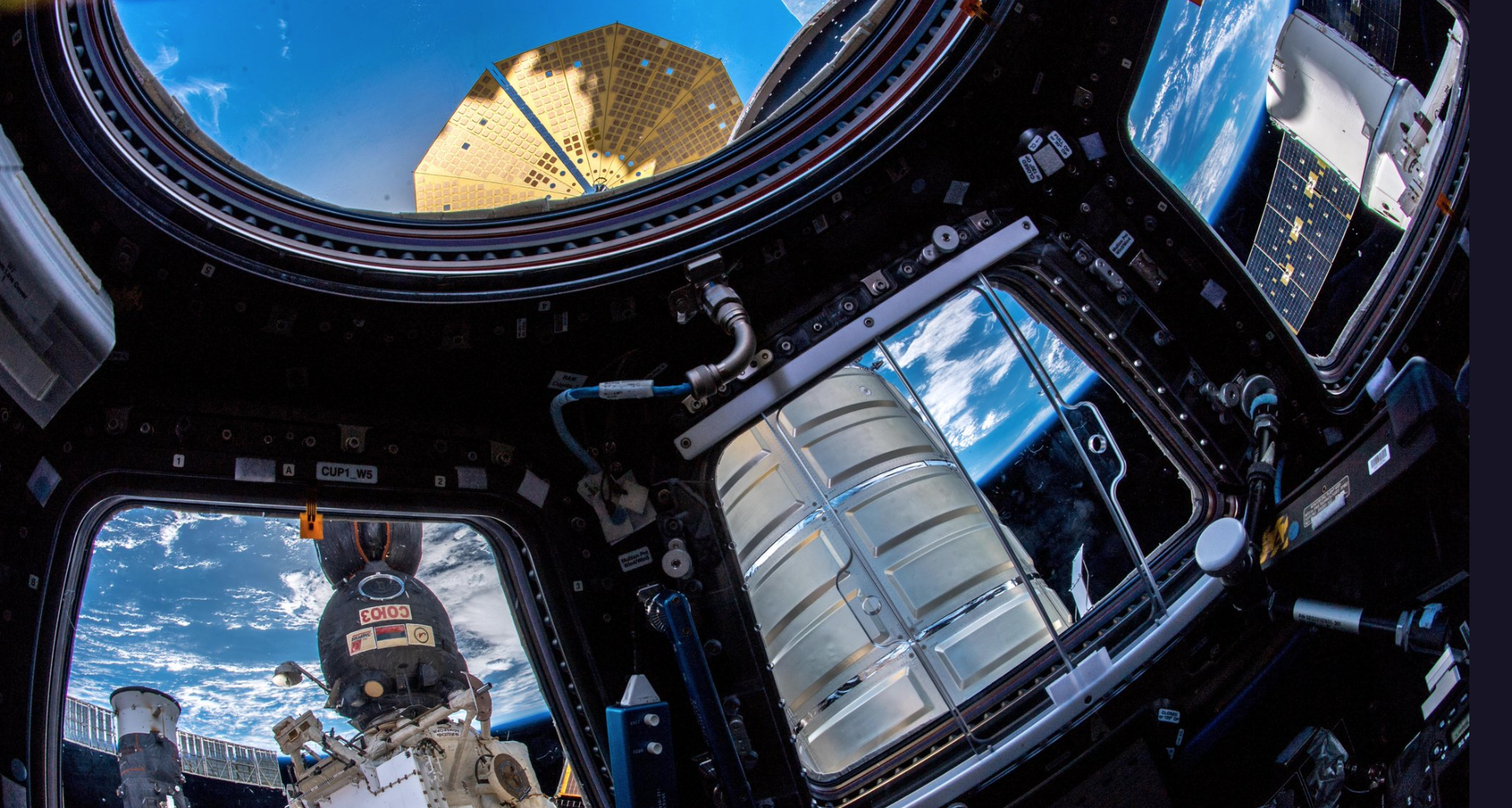

The researchers also used the material to create a craft that can float on the surface of water and then submerge in submarine-like fashion; further changes allow the craft to collect items with its hull before returning to form.

Future applications

The real-world applications of a shape-shifting robot like this have yet to be seen. The researchers suggest that the materials could be used to create machines that can self-repair, interface with humans in new ways, or even be worn. One promising aspect of the designs is that they are strong enough, at least at this scale, to withstand forces from motors and propulsion systems.

Still, this is not the first soft robot to be constructed. But the material used here is new and represents a different approach from existing models. Those models, which are designed for tasks as diverse as exploring the oceans or helping to improve mobility, are also in early stages of development. Beyond their abilities to shape shift or endure conditions that more traditional robots would struggle with, robots made out of soft materials would be safer for people to work with in many situations and may permit automation in situations where it is currently impractical or unsafe.